why do hardness testing|types of hardness testing methods : distribution Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well . WEBLuck Bet é um site de apostas esportivas e cassino online que oferece diversas opções de jogos, bônus e promoções. Entre no mundo da Luck Bet e divirta-se com segurança e .

{plog:ftitle_list}

卓越的执行力. 创 新. 诚 信. 愿景. 光电节能、智能科技最佳伙伴. 电源模块解决方案. 电源模块解决方案. 光宝集团自 1985 年以来一直生产开关电源,现在是全球最大的 3 家 OEM 商户开关电源供应商之一。. {{items.product.langData[0].title}}

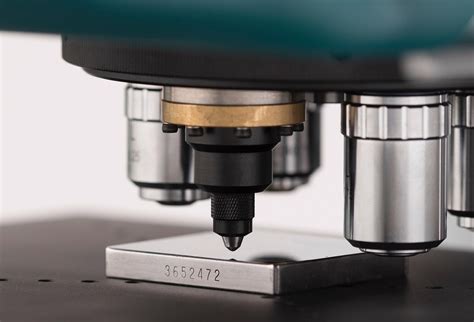

Hardness testing measures a material’s resistance to permanent deformation at its surface, by pressing a harder material into it. It is used in a number of industries for material comparison and selection, as well .What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications .

Hardness Testing is applied to a great number of materials, and for over 250 years, it has been an invaluable and frequently used mechanical test. A . The hardness of a material enables it to resist bending, scratching or cutting. The most common tests are the Rockwell, Brinell, & .Knowledge and insight into materialographic hardness testing – including how to test metallic and other materials, and the definitions, applications and conclusions of different hardness .

Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed.

Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.

Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the .Why Hardness Testing is Essential in Materials Engineering . Hardness testing is a pivotal part of materials engineering, acting as the definitive measure for a material's strength and .

why is hardness testing important

wood floor moisture meter lowes

The hardness of a material is its inherent property that allows it to withstand abrasion, bending, scratching, cutting or deformation. If your day to day work involves materials manufacturing, you are most likely aware of the importance of a hardness test in allowing you to evaluate the products received from external suppliers and also, the production process of . Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the hardness of metals, alloys, and plastics, when compared to .

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. From testing methods to the key applications, we cover it all to help you stay informed. . Here’s how to perform a total hardness test using strips: 1. Dip a Strip Into Your Pool. Take a test strip from the container, being careful to only touch the white areas of the strip itself. Any accidental touches of the colored pads will compromise the .High Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the

Why test for water hardness; 4 Methods to Test Water Hardness; 3 Steps For Managing Hard Water; 🤔 Understanding Water Hardness. Water hardness is typically measured in grains per gallon (GPG) or milligrams per liter (mg/L), which is equivalent to parts per million (ppm). Water is considered hard if it contains more than 60 mg/L (3.5 GPG) of .Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf.

wood floor moisture meter reviews

So, being able to do a hardness test provides a quick technique to identify minerals. Mineral hardness is essential since it indicates minerals’ chemical composition and structure. Knowing the mineral hardness helps to narrow down a list of possible minerals during sample identification. The hardness tests can clearly distinguish between two . Brinell Hardness Test: Diagram of Brinell Hardness Testing Machine. Brinell Hardness Test is one of the most important hardness tests in the engineering industry and metallurgy. It is used when the surface of the metal is very rough to use another hardness test on it. There are two methods to perform the Brinell hardness Test on the metal as .The Rockwell hardness test is widely used in various industrial applications, such as manufacturing, engineering, and quality control. It provides a quick and reliable measure of hardness, making it suitable for routine hardness testing on the produc-tion floor. Industrial Application The Rockwell test is particularly suitable for measuring theThe Brinell hardness test was originally developed in the late 1800s by the Swedish engineer of the same name. He wanted to find a method to control the quality/hardness of steel. His solution was to press a railway wheel-bearing ball into the material and then measure the size of the mark it left. The method proved reliable and in 1900 the .

In scientific terms, water hardness is generally the amount of dissolved calcium and magnesium in water. But in layman's terms, you may notice water hardness when your hands still feel slimy after washing with soap and water, or when your drinking glasses at home become less than crystal clear. Learn a lot more about water hardness on the Water Science . Summary/Annotation: This article from Buehler provides an in-depth overview of hardness testing, discussing different methods such as Rockwell, Vickers, Brinell, and Knoop hardness tests. It explains the principles behind each method, the types of materials they are best suited for, and how to properly conduct these tests.

The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. Brinell hardness testing is particularly suitable for thicker, heterogeneous materials in the low to medium hardness range! Thin sheets cannot be tested with the Brinell hardness test! The Brinell hardness test .A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .

Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for . Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing. Why is hardness testing used? The various hardness testing can be used for the following purposes. Quality inspections Many metals suppliers and metal manufacturers use different types of metal hardness testing to ensure the quality purposes. Typically, companies will test the hardness of material received from suppliers to ensure that material . Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness Testing Considerations The following sample characteristics should be considered prior to selecting the hardness testing method to use: • Sample Size • Cylindrical Samples • Sample Thickness

Why Hardness Testing is Essential in Materials Engineering . Hardness testing is a pivotal part of materials engineering, acting as the definitive measure for a material's strength and durability. Conducted under different loads, speeds, and temperatures, hardness tests offer invaluable insight into the performance of a material under various .

Hardness testing of welds can be performed on any Vickers micro hardness testing machine. When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph.

Mohs hardness test: When conducting the test, place the unknown specimen on a table top and firmly hold it in place with one hand. Then place a point of the reference specimen against a flat, unmarked surface of the unknown specimen. Press the reference specimen firmly against the unknown, and deliberately drag it across the flat surface while pressing firmly. Perform the Mohs Hardness Test. The Mohs hardness test is easily performed. You need examples of items with known hardness values. Handy materials include: your fingernails (2.5) a copper coin or piece of chalk (3.5) a pocket knife or piece of glass (4.5-5.5) a quartz point or unglaze porcelain (7.0) a hardened drill bit (8.5)

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to .The Knoop hardness test method is one of microhardness tests – tests for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. The Knoop and Vickers techniques are referred to as microindentation-testing methods on the basis of indenter size.

types of hardness testing methods

wood fuel moisture meter

WEB4 de nov. de 2022 · Wedeco was founded in 1976, located in Herford, Germany, and developed halogen-free and environment-friendly water treatment technologies, including ultraviolet and ozone systems. There are more than 250,000 Wedeco systems used for ultraviolet disinfection and ozone oxidation in private, public utilities and industrial sites .

why do hardness testing|types of hardness testing methods